Maximum IIoT security

meets the plug&play experience.

IIoT security, remote service, predictive maintenance: implementation of these aspects of IIoT fails for many manufacturers and operators of machines and systems because of a range of security concerns or the complexity of the task. Our solution here is called Big‑LinX®

with X-secure concept

One platform. X options.

Big‑LinX® provides manufacturers and operators of machines and systems with a versatile IIoT tool with which they can achieve their individual business objectives securely.

Xceed

IIoT Security

Choose smartcard technology from ADS-TEC that cannot be copied or read

Big‑LinX® for maximum security in IIoT activities

Xpand

Maintenance

Enjoy continuous access to machine data and flexible process design

Big‑LinX® for greater machine & system availability

Xtend

After Sales

Increase your turnover with individual after-sales service and customised support

Big‑LinX® for an effective boost in turnover

Xpress

Remote Service

Improve your service with faster response times and more efficient remote maintenance

Big‑LinX® for greater user satisfaction

How-to-Video series „Big-LinX® insights“

How does Big‑LinX® work?

The answers are provided by

our network and IIoT expert Marc Schmierer.

to our YouTube channel

Whitepaper including checklist

Industrial IoT Cloud Solution: What you should consider in your selection

Request download link

“Thanks to Big‑LinX® we can make our service much more efficient.”

Dirk Schmidt, Technical Manager Software/FMS, Amada GmbH

Dirk Schmidt, Technical Manager Software/FMS, Amada GmbH

Improve your maintenance intervals.

With no additional personnel.

Think Big‑LinX®.

By evaluating machine and system data through remote access, maintenance work can be scheduled effectively and organisational complexities reduced significantly.

- Solid basis for predictive maintenance

- Secure data transfer with our WWH protocol

- Fully configurable dashboard for a fast overview

Put your machine into operation.

Without being at the machine.

Think Big‑LinX®.

With the one-click connection option, you can put machines into operation easily and respond quickly to any problems that occur during commissioning.

- Easy login via Big‑LinX®

- One-click connection to the machine

- No costly travel to the machine location

Access machines in China securely and reliably. From anywhere.

Think Big‑LinX®.

With our China connection service, you can access machines in China securely and with no restrictions using tried-and-tested, reliable technology.

- „China Connection“ can simply be added as an optional extra

- No limitation on the number of machines

- Remote service guaranteed from anywhere

Design your own IIoT platform.

Without any specialist IT skills.

Think Big‑LinX®.

Thanks to the option for customised configuration in the factory, Big‑LinX® can create a genuine plug&play experience.

- Firewall pre-configured in the factory

- No complex integration of IT into the machine

- Easy to operate with drag&drop

Carry out maintenance work in areas of risk.

Without taking any risks.

Think Big‑LinX®.

With Big‑LinX®, you can save your service employees from having to make dangerous journeys into areas where there is currently a high risk of coronavirus by providing them with a versatile maintenance tool.

- Reliable alternative to service deployments in areas of risk

- Comprehensive maintenance by remote access

- One-click connection to the machine

Different ways to your optimal IIoT solution

Are you looking for expert advice on IIoT networking?

Write us.

Leading manufacturers and operators of

machines and systems opt for

Big‑LinX®.

And their success shows that they made the right decision.

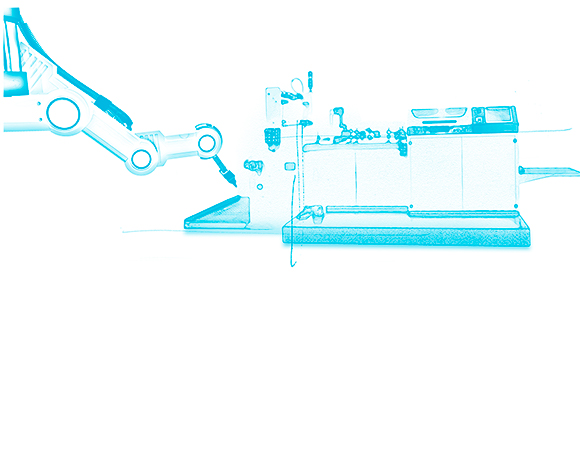

"Implementing Big‑LinX® into the terminal makes it possible for us to support our customers and partners fully, easily, reliably and as fast as possible. ADS-TEC is the ideal partner for us, as it has always adapted to our requirements flexibly ever since we began working together"

Thomas Mertes, Executive Partner, toolbox GmbH

Thomas Mertes, Executive Partner, toolbox GmbH

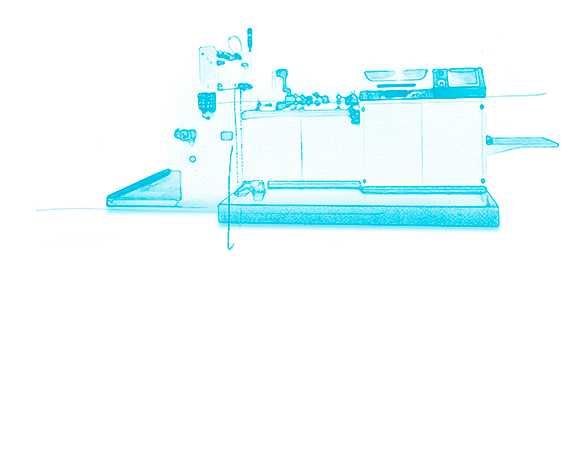

„Thanks to Big‑LinX® and the ADS-TEC firewall, we are able to grant the remote capability of our producer plants for solid wood processing machines, independent of the operating system. Even with outdated operating systems it is possible to provide remote service by our experts without material risks for the customer network. This as well will contribute to further reduce downtimes for our customers in the future. With the Big-LinX portal we currently manage more than 1,800 plants and machines worldwide. The user control enables us to also provide decentralised service locations with access to plants/machines that are relevant. With ADS-TEC we have found a reliable, secure partner who gives us the chance to grant LifeTime Services. This is one of many building blocks on our way to a continuous digitalisation of the service experience for our customers and installed base.“

Andreas Doikas, LifeTime Services/Group / Leitung | Vicepresident, Michael Weinig AG

Andreas Doikas, LifeTime Services/Group / Leitung | Vicepresident, Michael Weinig AG

"Thanks to Big‑LinX® we are able to check in advance which spare parts are required for a service job."

Dirk Schmidt, Technical Manager Software/FMS Amada GmbH

Dirk Schmidt, Technical Manager Software/FMS Amada GmbH

„Thanks to Big‑LinX® we can significantly accelerate the response time and the initial diagnosis on the target system. The downtimes in the event of a malfunction are considerably reduced. If the cause of the malfunction is clearly localised and it is purely a software problem, it can be sol-ved via Big‑LinX® / X‑Remote. By analysing the data via Big‑LinX® LinX of the target system the possible initial deployment of the service technician can be planned and executed in a targeted manner.“

Urs Stäheli, Director Software Engineering, HARDINGE

Urs Stäheli, Director Software Engineering, HARDINGE

„Our „smart“ ALLROUNDER injection moulding machines are able to „communicate“ as they have Basic Connnectivity with an IIoT-Gateway from ADS-TEC. This enables the provision of process and production data to higher-level software tools and platforms like the ARBURG host computer system ALS or the customer portal arburgXworld. In addition, the remote access to our machines takes place via a secure and encrypted connection. By saying that Big‑LinX® contributes immensely in shortening the response times. Our customers receive a fast, efficient and secure online support from our ARBURG experts in an event of problems.“

Gerhard Würth, Bereichsleiter Technischen Abwicklung, ARBURG GmbH + Co KG

Gerhard Würth, Bereichsleiter Technischen Abwicklung, ARBURG GmbH + Co KG

„Big‑LinX® enables us to monitor our globally distributed battery modules, store their lifecycle data as a digital twin and distirubte software updates to our storage systems and charging infrastructure facilities.“

Sascha König, Leiter Services, ads-tec Energy GmbH

Sascha König, Leiter Services, ads-tec Energy GmbH

The right application for any requirements.

With the Big‑LinX® IIoT platform, manufacturers and operators of machines and systems as well as Industry 4.0 service providers have a powerful modular application system at their disposal for various IIoT requirements.

One Click

Remote‑Service

Speed up access to your machine

Dashboards &

Dashboard Designer

Create dashboards for entire series of machines

Firmware

management

Plan and carry out firmware updates

Virtual

machines

Create software templates for machines

Innovative services for a secure IIoT.

simple and secure remote maintenance, connection to decentralised systems and device management.

MaXimum IIoT

MaXimum benefit to you.

Unique IIoT security concept.

Implemented consistently.

Questions to Big‑LinX®?

We will be happy to help.